BEST-PRACTICE FOR LIVESTOCK VACCINES > VIDEO

Listen to this audio from the Head Shepherd podcast series to learn how to avoid common costly mistakes with vaccines to deliver a better result for the animal and maximise the return on investment for farmers.

BEST-PRACTICE FOR LIVESTOCK VACCINES > FACT-SHEET

ABOUT THIS PODCAST

This podcast was produced as part of neXtgen Agri’s Head Shepherd Podcast series. Covering all things livestock through the amazing stories of farmers and the people that study them. Allflex and MSD Animal Health are a proud sponsor of the series and we highly recommend you have a listen to more of the podcasts.

For more visit: www.nextgenagri.com/head-shepherd-podcast

VACCINES & VACCINOLOGY

While vaccines are not particularly complex, they are all slightly different in their makeup which means they all need to be used in slightly different ways. This is why each vaccine is accompanied by a product information sheet (often referred to as ‘the label’) which states precisely how the product should be used and what you

can expect as a result.

To download a copy of the production information label for any registered New Zealand veterinary

medicines check out the ACVM register on the New Zealand Food Safety website:

https://eatsafe.nzfsa.govt.nz/web/public/acvm-register.

This podcast details the team at MSD Animal Health’s experience with common mistakes that farmers are making when using vaccines and how small changes could help avoid these costly mistakes, deliver a better result for the animal in terms of its health, and maximise the return on investment for farmers. In short, farmers are paying for these vaccines and we want to make sure they get the most bang for their buck.

COMMON VACCINE MISTAKES

Incorrect:

- Timing

- Interval between doses

- Dose

- Site of administration

- Method of administration

- Needle and vaccinator gun hygiene

- Storage

In addition, another common mistake is not giving a full vaccination course or not vaccinating healthy, clean, dry well-fed animals who are under minimal stress at the time of vaccination.

Timing:

Timing is an important consideration for vaccines for two main reasons. Firstly, it’s important to time the vaccination course so the vaccine is given prior to the risk period for the disease. This is because the resulting antibody level, and hence protection from the vaccine, needs to be as high as possible at the time of the greatest disease challenge or risk. A second reason timing is important is when optimum colostral antibody levels are required for passive immunity. A good example of this is vaccinating ewes against clostridial diseases pre-lambing, which provides not only the ewe protection, but also provides short-term protection to her offspring via antibodies in her colostrum while the lamb develops its own antibodies to fight disease.

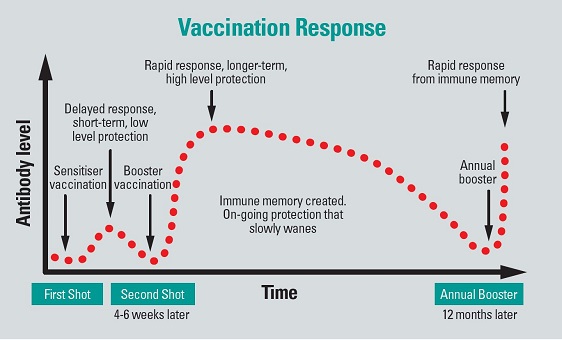

Interval between doses:

The interval between doses as specified on the product information label is important. If the sensitiser and booster doses are given too close together, or too far apart, then this can negatively impact on the animal’s immune response. Equally, if annual boosters are given beyond 12 months apart, then this can also affect the ability of the animal to respond to the vaccine due to loss of the immune system’s memory.

Dose:

Different vaccines have different dose rates. Some vaccine dose rates are weight dependent while others are not. Therefore it’s imperative that you read the label to determine the correct dose rate for the animal in question. In addition to this, it is important to check that your vaccinator gun is delivering the intended amount.

Site of administration:

The approved and recommended vaccination site is the anterior third of the neck unless otherwise stated on the product information label. By adhering to this recommendation, should an injection site lesion occur, then it will be easy to trim from the carcass at slaughter and avoid site lesions occurring in the premium meat cuts.

Method of administration:

Some vaccines are to be administered subcutaneously (under the skin) and other are administered intramuscularly (into the muscle). Refer to the products information label for the recommended administration route for each. When administering subcutaneously it is recommended to ‘tent the skin’ as per the illustration below

In addition, when administering vaccines, slow and steady wins the race. Slowing down and taking care will yield a better result and minimise the risk of injection site lesions.

Needle and vaccinator gun hygiene:

- Use sharp needles.

- Change needles frequently (every 20 animals).

- Needles and vaccinator guns should be sterile before starting. Needles can be sterilised by boiling for 10 minutes and storing in methylated spirits.

Storage:

It’s important to note that when it comes to correctly storing vaccines – it’s not just how it’s stored prior to use, but it’s also how the vaccine is handled from the point of purchase to the farm, or even from the refrigerator on farm to the yards just prior to use. While many will store the vaccine as per label instructions in the fridge, some will overlook the effect of having the vaccine sitting in the hot sun at the yards, or on the seat of the ute or quad. Incorrect temperatures can destroy the vaccine, or cause a suboptimal result, wasting not only your investment in the vaccine but also the time spent administering the vaccine. Simply transporting vaccine in a chiller bag at all times will ensure the product has the best chance of delivering what it promises.

As well as storing correctly prior to use its important to consider storage after use of partially used packs. Exactly how long a partially used pack can be kept and used will be specified on the product label, but to protect the integrity of the product, the following steps should be taken:

- Store away from light at 2°C to 8°C.

- DO NOT FREEZE.

- Store locked up and take the following steps:

- Carefully remove the draw off tube from the rubber stopper

- Empty the draw off tube and vaccinator by depressing the plunger several times.

- Remove the draw off tube from the vaccinator gun.

- Disinfect the stopper by wiping it with a clean cloth soaked in methylated spirits.

- Store the vaccine in its original cardboard carton and place upright in the refrigerator

- Re-use with sterile needles, vaccinator gun and draw-off tube

IMPORTANCE OF COMPLETING A FULL VACCINATION PROGRAMME

A full vaccination programme for killed vaccines (most common vaccine type) is normally two shots (sensitiser (1st shot) and booster (2nd shot)) in the first year of use, followed by an annual booster thereafter.

The reason most vaccines require two shots the first time they are used is because the sensitiser only induces a small antibody response which is usually not very protective and is short-lived (lasting only a few weeks). If the animal is given a booster (a subsequent dose) at the right time, a stronger and longer lasting antibody response occurs which affords the animal more enduring protection. That’s why if the product label specifies two shots, both shots must be given to provide long-lasting, effective immunity. Some vaccines such as Toxovax are live and only require one-shot in order to provide lifetime immunity.

As always, if you are unsure how to best administer vaccines, or have any other questions, you are encouraged to contact your animal health advisor who can help answer questions and provide the necessary training.

Further to this, you can check out the following useful videos on how to prepare and administer vaccinations.

www.sheepvax.co.nz/how-to-prepare-for-vaccination

www.sheepvax.co.nz/how-to-administer-a-vaccination

FOR MORE:

Or find us on YouTube by searching: TopFarmersNZ

Or visit: soundcloud.com/TopFarmers

Or visit: msd-animal-health.co.nz

Top Farmers Know-How provides a reference library of industry best practice in some key animal health management areas including mastitis, dry off, calf health, BVD, salmonella and campylobacter. We know that farmers and vets are busy people, so we’ve created resources in different formats and in bite-sized chunks to make it more flexible and accessible.